For about the last 20 years, the demand for moulded fiber packaging has been increasing, and more recently has exploded. Manufacturing technology has followed except for the key component: tooling. Almost all global molded fibre product producers currently use the same tooling of 3D machined metal, with extensive drilling and difficult metal screening. This tooling process is costly as well as requiring long delivery times for products. Tooling (moulds) has been a manufacturing pain point for many years in spite of many attempted improvements.

HP, in their efforts to address environmental sustainability, saw an opportunity to apply their sophisticated technology to the tooling issues in the moulded fibre industry. They engaged in a year-long project to understand the needs of moulded fibre product manufacturers, while commencing engineering studies and production testing. The result is HP Molded Fiber Advanced Tooling Solution, the first new functional tooling advancement in the moulded fibre industry in decades.

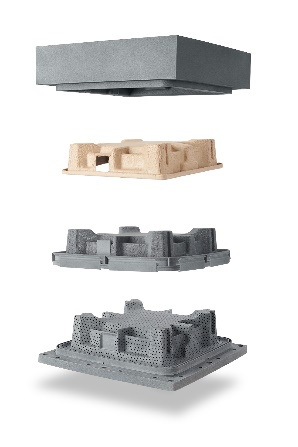

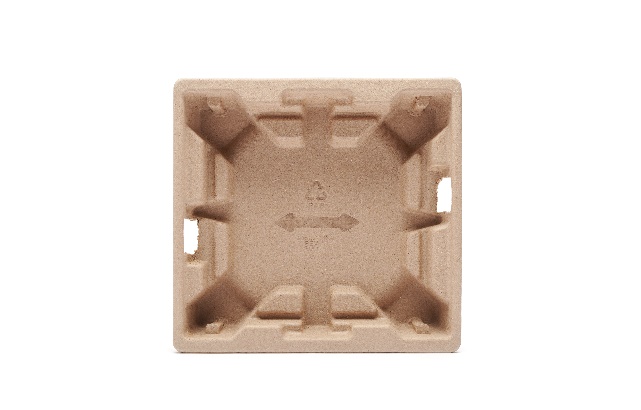

The HP Molded Fiber Advanced Tooling Solution incorporates light weight tooling components using HP’s industry-leading 3D printing and digital manufacturing expertise, technology, and software capabilities. This proprietary process creates the mould body with integrated fluid transfer ports (no drilling), a pre-formed screen with special performance characteristics, and the capability to easily change screens.

Both manufacturers of moulded fibre packaging and their customers will benefit with HP’s new breakthrough technology by way of significant manufacturing efficiencies, product feature opportunities, and packaging product quality. It is another of HP’s contribution to global environmental sustainability.

HP’s new technology,”Advanced Molded Fiber Tooling Solution” is now available as a direct replacement for current tooling and new tooling requirements.

For more information contact https://hp.com/go/moldedfibertooling