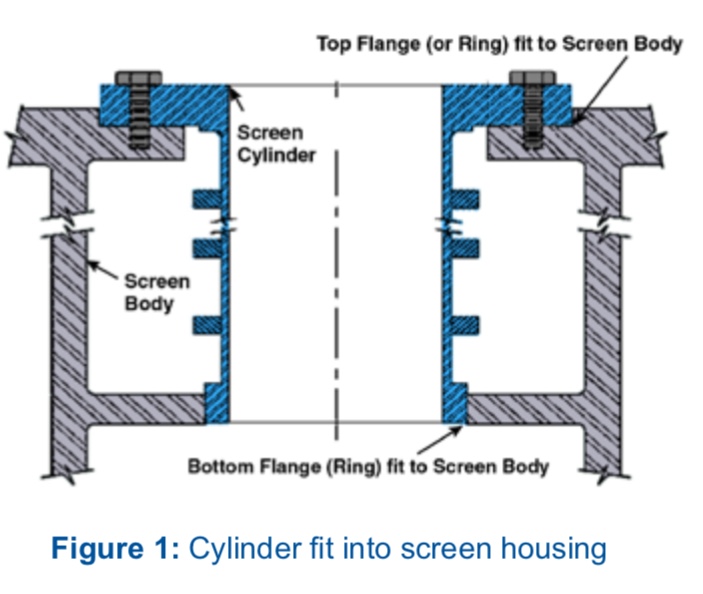

A primary cause for cylinder breakage is wear in the base of the screen housing. It is where the cylinder is positioned into the housing, as shown in Figure 1. The interface design of the housing and cylinder make a “fit”. Maintaining the fit is critical in keeping the cylinder stationary and operating properly. A loose fit can be indicated by vibration and cylinder movement.

Damage can show itself in many ways, including:

1. Wear in the housing fit area

2. Increased vibration of the screen

3. Additional stress on the top fit where the cylinder is bolted and eventual bolt breakage

4. Movement of the cylinder causing inefficient surface cleaning – leading to poor debris removal

5. Additional stress on the cylinder leading to breakage

6. Loss of efficiency in the filtration process

A regular screen inspection is the most critical maintenance step to prevent pressure screen failure. Inspection frequency will depend on the screening process and typical wear tendencies. To learn how to conduct our 5-step inspection, follow this link:

https://aft-global.com/resources/screening-news-screen-body-cylinder-fit