27 Apr. 2025: Recycled fiber Pulping is one of the corner stones of the board making process, and its efficiency directly impacts the quality and cost-effectiveness of the production line.

However, mills using recycled paper face issues such as sustaining pulping yield, optimizing maintenance schedules, and adapting to raw material quality variations. Managing these challenges adequately is important for overall production line yield and consistent paper quality.

In this blog, I’d like to share some insights into how Aikawa Fiber Technologies has helped customers improve their operation. We at Aikawa Fiber Technologies understand the complexities recycled paper mills encounter daily. Recognizing that every mill has unique challenges, a tailored approach is essential. Our solutions are designed to address specific operational needs, delivering measurable improvements in productivity and quality.

Tackling variability in raw materials

When it comes to pulping processes, there are several “everyday” factors that cause unpredictability. In the short term, one of the key things to deal with is the variability in raw materials. Different sources bring a mix of paper qualities and even those considered "reliable," such as supermarket-origin collection, can still have batch-to-batch differences. This means that adjustability and adaptability in process / equipment design is essential. A well-designed recycling paper detrashing system can manage excess reject content while maintaining effective reject removal performance.

In a well-engineered pulping system, reject removal can be adjusted during operation. When reject content is low, less detrashing is required. When reject content increases, the system adapts to handle higher reject loads. Detrashing system must be capable of handling increased detrashing demands, by accepting more flow and being able to push more waste to the WashDrum. Capacity tolerance is not only about the equipment sizes, but every component in the system matters, including pipe sizes, valves size, pumps and motors, etc.

The WashDrum must be capable of efficiently washing and pre-dewatering of rejects, so fibers are recovered and re-processed in pulping, and discharged waste is fed to further processing with less free water. Most importantly, regardless of reject quantity variations, all waste should consistently exit the reject wash drum, ensuring high pulping yield.

Figure 1: Even large contaminants must be effectively removed from the system. For example, in this picture a tennis court net is being rejected via WashDrum.

Long-Term Challenges: Wear and Maintenance

Over the long term, mills face various challenges related to wearing on key components, such as rotors, deflaking elements and screening parts. The operational characteristics of these key components diminish due to the wear caused by contaminants within the raw material.

Mills highly value solutions that can identify underlying issues without requiring machine downtime. How can this be achieved?

Equipment issues are often shown as high fiber content in the rejects coming out of the pulping process. This usually means that the system has been operating out of target parameters for quite some time.

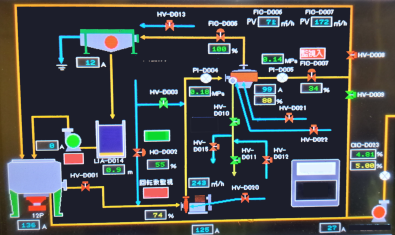

Figure 2: Comprehensive process and equipment instrumentation is key to detect wear related issues in the system.

Process performance can be monitored through process indicators, before the issues become visible. When machine parts start to wear out, their performance begins to decline and process units are not operating within parameters (such as flow, power or pressure, etc.) that were set when the spare parts were last replaced. A simple comparison of current operating parameters with historical data can serve as a helpful tool to define whether near future maintenance actions are necessary.

Process stability and quality control are directly linked to how a pulping system is set up. A well-designed pulping system must be flexible in operation so that adjustments to a single unit do not disrupt the entire process. When a system is easy to operate, pulping capacity can often be increased beyond design capacity and quality.

Scheduled Maintenance and Efficient Wear Part Management

Replacing wear parts should ideally be performed during scheduled maintenance activities. In the initial stages of wear, adjusting the clearance between the rotor and screening element may be sufficient rather than replacing entire components. Aikawa Fiber Technologies’ equipment is specifically designed to facilitate simple adjustments without full unit disassembly. This approach reduces emergency maintenance efforts and ensures that replacement tasks can be efficiently incorporated into planned maintenance schedules, optimizing both time and resources.

Figure 3: Replaceable and adjustable rotor wear elements make rotor maintenance easier and quicker.

Efficient wear parts inventory management is essential for completing maintenance tasks on time and minimizing downtime. Aikawa Fiber Technologies offers maintenance services and inventory agreements to ensure that the required parts are readily available and can be replaced in a timely manner.

With Aikawa Fiber Technologies service agreement, our team works at the mill to assist customers. This allows the mill personnel to focus on production and key operational tasks and receive expert support for maintenance activities that require specialized knowledge.

The service contracts also serve as a valuable training platform for mill maintenance teams. Many tasks are performed collaboratively, thus transferring expertise to mill personnel for future maintenance activities. This approach not only ensures smoother operations but also enhances the mill's long-term self-sufficiency in maintenance.

At AFT, our mission is to help mills get more from their systems. If you have ideas, needs, or pulping related challenges, don’t hesitate to reach out to us at Aikawa Fiber Technologies. Contact Olli-Pekka Riippa directly by email This email address is being protected from spambots. You need JavaScript enabled to view it. or send us a contact request through the form on our website. We’re here to help!